- kamatamogh@airochem.co.in

- +91 9011068031 / 9822833300

Dust Collection

Industry-Leading Dust/Fume Collection Systems

At Airochem, we specialize in designing and executing high-performance dust/fume collection systems tailored to meet the unique needs of various industries. Our solutions are engineered to deliver exceptional efficiency, ensuring a cleaner and safer environment in industrial settings.

Industries Served

- Sugar Industry

- Advanced systems for dust collection in sugar houses and packing houses, ensuring minimal dust dispersion and improved air quality.

- Foundries Customized solutions for

- Tumbling barrels

- Pouring stations

- Sand handling plants

- Knockout operations

Source-Level Dust Collection

Our systems are designed to capture dust at the source, utilizing the principles of local exhaust ventilation. This ensures optimal air quality and minimizes the spread of dust in the workplace.

Dust collection system executed recently for Sand Reclamation plant at Kolhapur Foundry cluster

Key Features of Dust Collection Systems

- Compliance with Global Standards

- Exhaust rates are meticulously calculated as per the Handbook of Recommended Practice by the American Council of Industrial Hygienists (ACGIH).

- Engineer-Driven Solutions

- Our team of trained engineers develops exhaust requirements based on fundamental principles of local exhaust ventilation, ensuring the success and reliability of every system.

- Wide Range of Filtration Options

- Pulse Jet Bag Filters

- Reverse Air Cartridge Filters

- Solutions designed for applications ranging from high-dust industrial environments to sensitive processes requiring fine particle filtration.

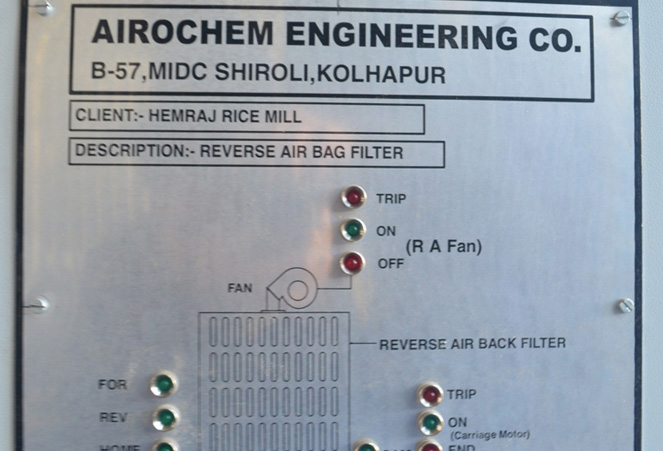

- Custom Control Systems

- Control Units with Electrical Switchgear Panels : Designed for efficient operation, such as our 20 TPH boiler fly ash control unit.

Benefits of Airochem Dust/fume Collection Systems

- Enhanced Workplace Safety

- By effectively capturing dust at the source, our systems minimize airborne particulate matter, improving air quality and ensuring worker safety.

- Industry-Specific Expertise

- Solutions tailored to the specific needs of industries like sugar production, foundries, and boiler operations

- Energy Efficiency

- Optimized exhaust rates and efficient filtration systems reduce energy consumption, lowering operational costs.

- Durability and Low Maintenance

- Designed for long-lasting performance with minimal maintenance, ensuring a lower total cost of ownership.

We make Pulse jet Bag Filters, reverse air cartridge type filters.

This Photo is of control unit with electrical switch gear panel for 20TPH boiler fly ash control unit.